お客様のブランドに合わせたOEM/ODMソリューション

カスタムジャケットメーカー

- 30年以上 経験

- 中国・海外生産拠点

- サンプルタイム: 7~15日

- 大量生産: 45~60日

- MOQ : フレキシブルMOQサポート

コレクション OEM/ODMジャケット

Honry Apparelでは、メンズとレディースのジャケット製造に特化し、お客様のブランドのビジョンに合わせたファッション性の高い機能的なアウターウェアをお届けしています。高度な生産能力と30年以上の経験により、生地、トリム、フィット感、ロゴ、刺繍、ハングタグ、パッケージなどのブランディング要素に渡るカスタマイズをサポートします。新しいラインを立ち上げる場合でも、既存のラインを拡張する場合でも、当社のジャケット製造ソリューションはお客様のビジネスに合わせて拡張できるように構築されています。

コレクション OEM/ODMジャケット

Honry Apparelでは、メンズとレディースのジャケット製造に特化し、お客様のブランドのビジョンに合わせたファッション性の高い機能的なアウターウェアをお届けしています。高度な生産能力と30年以上の経験により、生地、トリム、フィット感、ロゴ、刺繍、ハングタグ、パッケージなどのブランディング要素に渡るカスタマイズをサポートします。新しいラインを立ち上げる場合でも、既存のラインを拡張する場合でも、当社のジャケット製造ソリューションはお客様のビジネスに合わせて拡張できるように構築されています。

スエードジャケット

滑らかでベルベットのような仕上がりのスエードジャケットは、カジュアルにも高級なコレクションにも洗練されたスタイリッシュなタッチをもたらし、秋冬の装いにぴったり。

選ぶ理由 ホンリー・アパレル

プレミア・カスタム・ジャケット・メーカーとして

30年以上の経験

強力な研究開発と設計

高速サンプリング

海外施設

安定した多様なサプライチェーン

厳格な試験基準

持続可能な製造

ワンストップOEM/ODMソリューション

パフォーマンス・ファブリックス カスタムジャケット

プロのカスタムジャケットメーカーとして、Honry Apparelは様々な気候と機会に適した高品質の生地を幅広く提供しています。認証された生地サプライヤーの信頼できるネットワークに支えられ、一貫した品質と信頼できる調達を保証します。また、Oeko-Tex、SGSなどの試験認証を受けた素材を提供し、安全性と性能を保証します。

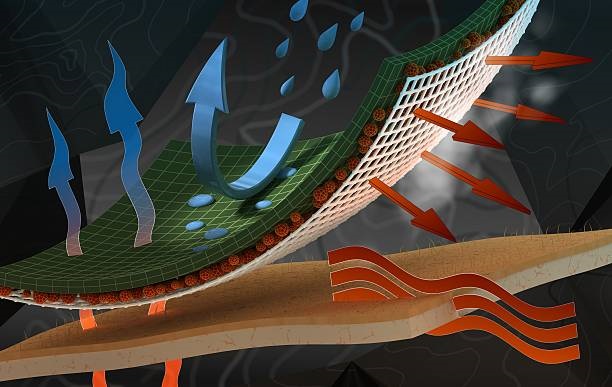

防水ファブリック

防風ファブリック

リップストップ生地

断熱素材

フリース生地

スエード生地

ソフトシェル生地

オーガニックコットン

防水透湿素材

シームテープ加工やアウトドア・ジャケットに理想的なこれらの生地は、多層ラミネート(PU、TPU、ePTFE膜など)と耐久性のある織物シェルを組み合わせ、雨や雪に対する完全なプロテクションを提供すると同時に、水蒸気を逃がす。

防風ファブリック

冷気を遮断し、保温性を保つように設計された防風素材は、パーカやパフジャケット、軽量ウィンドブレーカーによく使われている。これらのしっかりと織られた素材は、耐久性のあるコーティング加工が施されたり、裏地と接着されていることが多く、柔軟性と通気性を保ちながら風に対する効果的なバリアを形成する。

技術・試験能力

Honry Apparelでは、精度とパフォーマンスが製造工程の中核です。素材の準備から衣服の最終検査に至るまで、私たちは最先端の技術を駆使し、お客様の製品が機能性、耐久性、職人技の最高基準を満たしていることを保証します。

パフォーマンス・テスト

すべての素材と完成品は、色落ち、耐摩耗性、防水性、透湿性、耐風性、保温性、総合的な耐久性など、厳しい社内テストを受けています。これらのテストにより、すべてのジャケットがターゲット市場の期待性能を満たし、国際的な品質基準に準拠していることが保証されます。

レーザー切断

当社のレーザー・カッティング技術は、テクニカル・テキスタイルを中心に、さまざまな生地に超精密できれいなエッジ・カットを提供します。これにより、サイズの一貫性を確保し、生地を最大限に活用し、素材の無駄を最小限に抑えます。大量生産の効率と精度を高めることで、洗練された仕上げと優れた構造的完全性を備えた高品質のカスタム・ジャケットを生産しています。

テンプレート・キルティング

自動テンプレート・キルティング・マシンを使用することで、中綿を必要とするジャケットに一貫した高品質のキルト・パターンを提供しています。この技術により、カスタマイズ可能なステッチ・デザインが可能になると同時に、大量生産における構造的完全性と見た目の美しさを確保することができます。

テンプレート・キルティング

自動テンプレート・キルティング・マシンを使用することで、中綿を必要とするジャケットに一貫した高品質のキルト・パターンを提供しています。この技術により、カスタマイズ可能なステッチ・デザインが可能になると同時に、大量生産における構造的完全性と見た目の美しさを確保することができます。

シームシーリング(ヒートシールテーピング)

アウトドア・ジャケットや防水ジャケットに高度なヒートシール・テーピングを施し、水の浸入を最大限に防ぎます。この工程では、熱接着テープが衣服の縫い目に貼られ、従来の縫い目なしで生地の層が接着されるため、高度な耐候性が要求されるレインウェアやスキージャケット、アウトドアウェアに不可欠です。

連絡を取る

カスタムジャケットのプロジェクトを実現する準備はできていますか?個別のお見積もりと専門家の指導をご希望の方は、今すぐご連絡ください。お問い合わせには24時間以内に対応いたします。